Description

TYPE: Automatic integrated line for filling, capping, labeling and printing of liquid products, featuring Industry 4.0 digital management and remote control capability.

KEY FEATURES: Complete production line for liquid bottling with a continuous process that integrates filling, capping, labelling and product identification. Industry 4.0 architecture, allowing remote monitoring of operating parameters and remote technical assistance. Construction in AISI 316 stainless steel, with titanium in the filling area, making the line suitable also for highly oxidizing substances, disinfectants and aggressive products. Modular system allowing relatively quick format changeovers and handling of a wide range of bottle sizes. Fully equipped end-of-line with ancillary equipment (tape wrapper and compressor).

TECHNICAL FEATURES:

Brand 7FLUSS / TECNOFLUSS

4 titanium filling stations

Capping station for screw caps and triggers

Labeler with integrated printer

Bottle loading, unloading and accumulation tables

Bottle formats handled from 50 ml to 2 liters

End-of-line with ROBOPAC ROBOTAPE 50 CF case taper

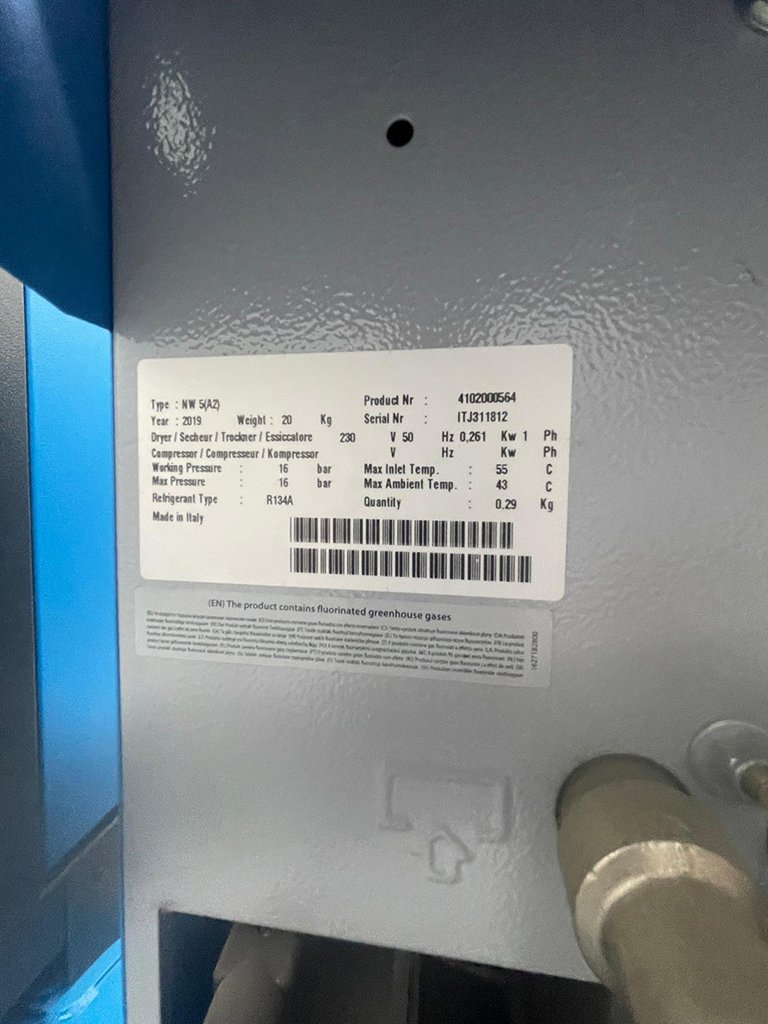

Service compressor: ABAC B5900 LN 5.5 DRY

User manuals, technical documentation and format change video instructions included

CE

PRODUCTION SPECIFICATIONS: The line is designed for automatic filling of liquid products into bottles of different formats, ensuring continuous processing from filling to carton closure. Thanks to the four filling stations and integrated digital management, the line ensures stable and controlled production, with real-time monitoring of process parameters and remote intervention when needed. The presence of accumulation tables and an automatic tape wrapper optimizes bottle flow at the end of the line and improves overall logistics. The stainless steel 316 and titanium construction makes the line suitable not only for food applications, but also for disinfectants and chemically aggressive liquids. Hourly output varies depending on product type and bottle format.