Description

TYPE: Thermocompression distiller with integrated pure steam generator, designed for the continuous production of Water for Injection (WFI) and Pure Steam as critical utilities in pharmaceutical plants. This technology is widely used in the industry for WFI production thanks to its high energy efficiency, achieved through heat recovery by vapor recompression.

KEY FEATURES: Compact and fully integrated skid system for the production of WFI and pure steam using vapor compression distillation technology. This solution is well known in the pharmaceutical industry for its reliability and low energy consumption. The unit combines the distiller and the pure steam generator in a single structure, ensuring continuous operation and stable process parameters. Sanitary stainless steel construction for all product contact parts, automatic management of operating cycles and high-temperature CIP phases, and central utility configuration make the system suitable for GMP environments and critical applications such as equipment washing, sterilization and pharmaceutical process support.

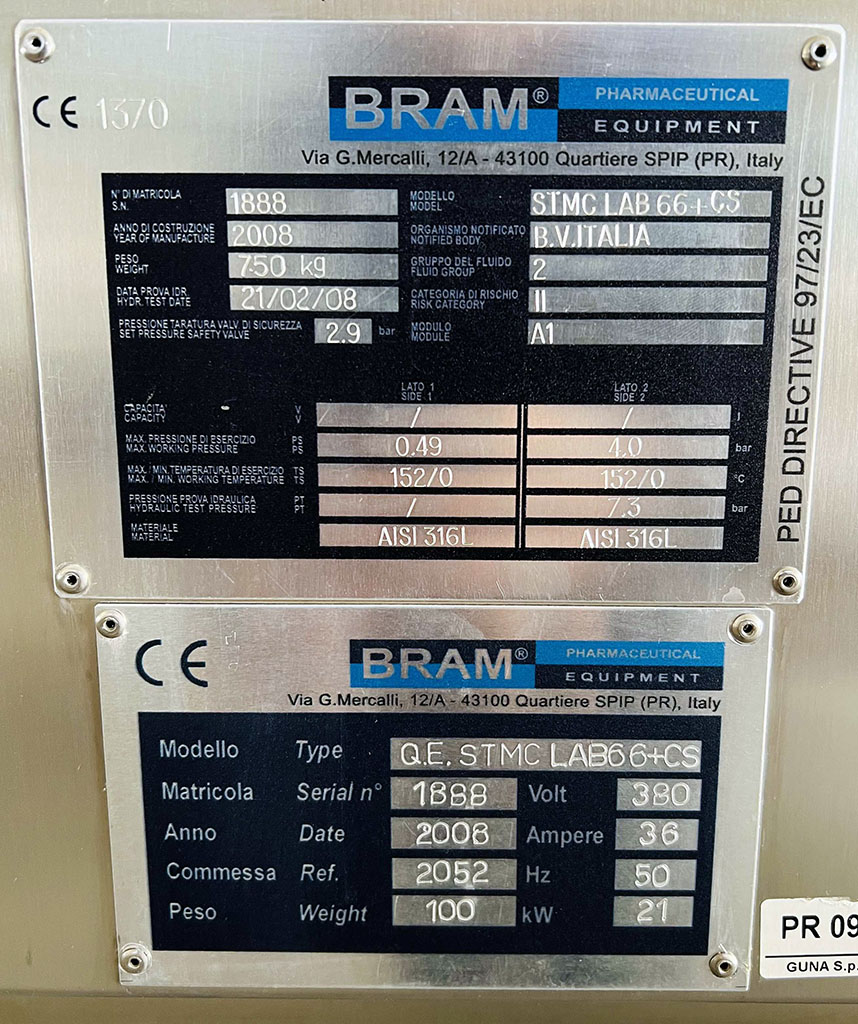

TECHNICAL FEATURES:

Power supply: 400 V – 50 Hz

Total installed power: 21 kW – 40 A

WFI distillate capacity: 66 l/h @ 1.2 bar

WFI outlet temperature: 60 °C

WFI pump flow during CIP: 4,200 l/h @ 2 bar

WFI temperature during CIP: > 90 °C

Pure steam capacity: 10 kg/h @ 2.5 bar

Pure steam outlet temperature: 139 °C

Compressed air pressure: 6 bar

Compressed air consumption: 2 Nl/min

Feed water inlet: 75 l/h

Feed water inlet temperature: 15 °C

Feed water for CIP: 1,500 l/h

Cooling water for drains: 1,000 l/h @ 2 bar

Cooling water inlet temperature: 15 °C

Maximum working temperature: 135 °C

PRODUCTION SPECIFICATIONS:

Designed for continuous production of Water for Injection (WFI) with a capacity of 66 l/h, suitable for constant operation supplying washing systems, sterilization processes and GMP critical utilities. Pure steam production up to 10 kg/h, suitable for sterilization and process services. The system supports high-temperature CIP cycles (>90 °C) with high flow rates, ensuring effective cleaning and reliable operation. Actual performance depends on feed water quality, available utilities and operating conditions.