Description

TYPE: Hot/cold vertical stainless steel mixer, equipped with an external jacket and internal coil for product temperature control. Designed for mixing and thermal treatment operations within a single vessel, it allows controlled heating and cooling cycles, ensuring product uniformity and process stability.

KEY FEATURES: Stainless steel construction with load cells, suitable for process applications. The external jacket and internal coil allow efficient control of heating and cooling phases, making the mixer suitable for temperature-sensitive products. The agitation unit is supplied without the bottom motor, which is not included; however, the machine is structurally prepared for the installation of a new agitation system. This intervention can be easily carried out by our technicians, without invasive modifications or technical criticalities.

TECHNICAL FEATURES:

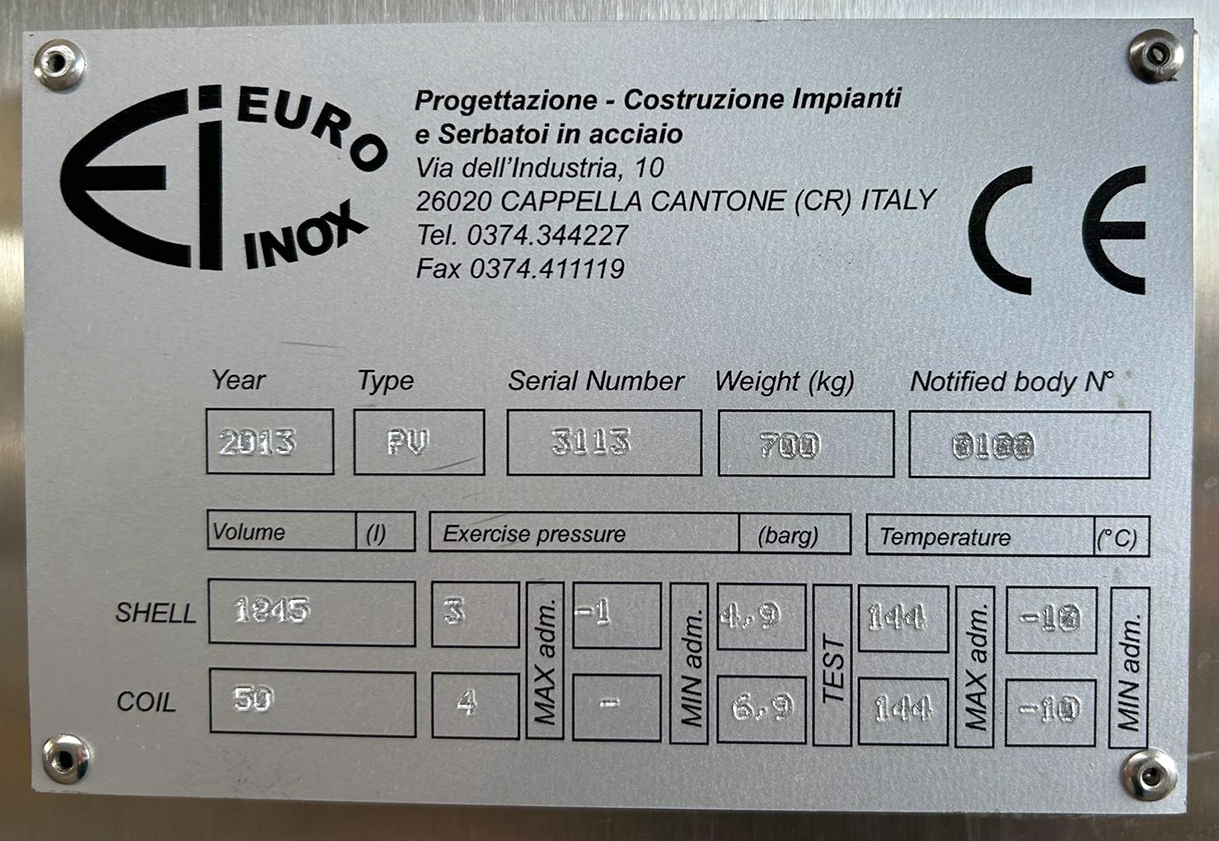

Vessel capacity: approx. 1,845 liters

Internal coil capacity: 50 liters

Operating pressure:

Vessel: 3 bar

Coil: 4 bar

Test pressure: 6.9 bar

Operating temperature range:

Maximum temperature: +144 °C

Minimum temperature: –10 °C

Machine weight: approx. 700 kg

Stainless steel electrical control panel

“CE”

PRODUCTION SPECIFICATIONS: Production capacity suitable for medium to large batches. Output and cycle times depend on the processed product.