Description

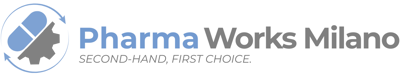

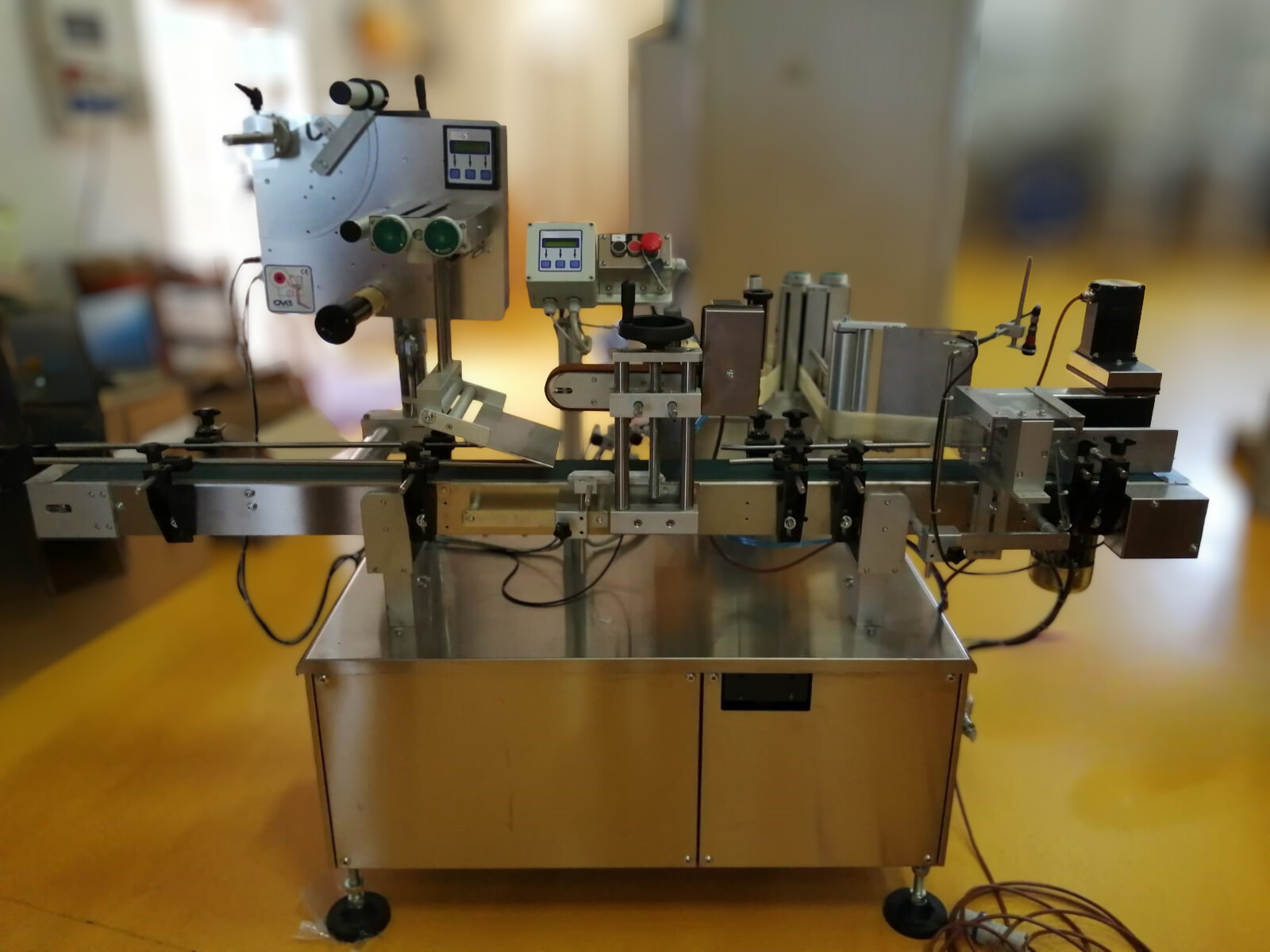

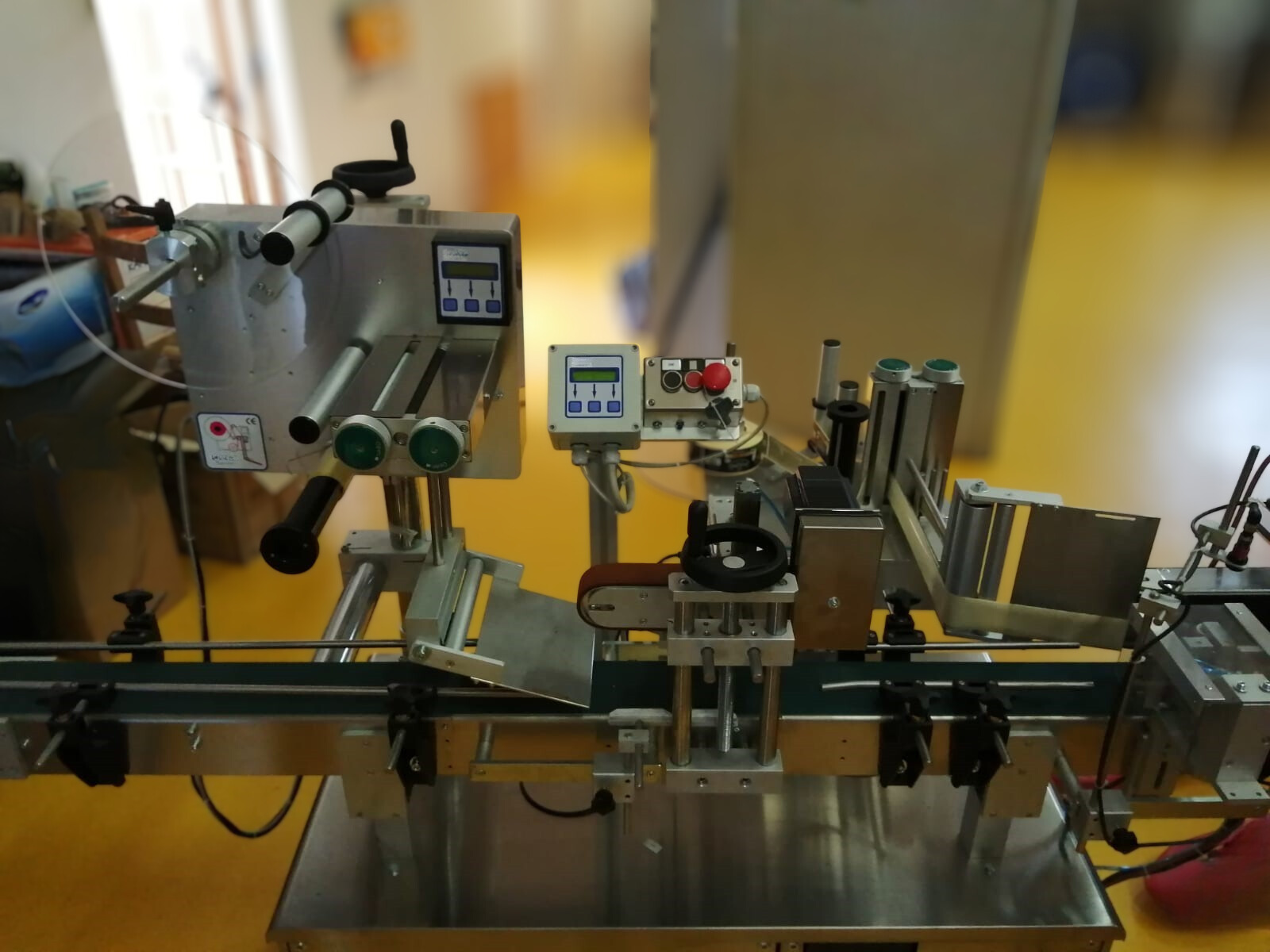

TYPE: Front/back labelling machines for the application of self-adhesive labels, with standard configurations or customized solutions based on specific customer requirements, which can be integrated with an optional head for security seal application.

KEY FEATURES: The front/back labelling line is designed to ensure high precision, reliability and operational flexibility in production environments ranging from small industrial facilities to higher-capacity plants. The machines can be supplied in standard configuration or customized according to specific application needs, allowing front and back labelling, front-only labelling, back-only labelling or the application of security seal labels. The system integrates a main motorized conveyor belt with inverter for fine adjustment of the transport speed and a W.A. roller unit with stepper motor, ensuring stable and uniform label application even on containers of different geometries. To complete the line, a dedicated head for security seal application is available, installable both on double-head versions and on single-head labelling machines. The seal label is applied on the cap or on the opening area of the package: at first opening it tears, allowing immediate verification of product integrity. This solution is widely used for jams, preserves and long shelf-life products, as well as in cosmetic and nutraceutical applications where a visual guarantee of tamper evidence is required.

TECHNICAL FEATURES:

Marking CE

Main conveyor belt drive with A.C. gearmotor and inverter for speed regulation

W.A. roller unit with stepper motor

Conveyor belt length 2,000 mm

Working height 900 mm ± 50 mm

Standard power supply 220/240 V – 50/60 Hz – single phase

Power consumption 800 W

Machine weight approx. 320 kg

Dimensions 2000 (L) × 1200 (W) × 1100 (H) mm

Protection rating IP 41

Noise level at 1 m 70 dB

Suitable container formats: round bottles/jars; square bottles/jars; oval bottles/jars; hexagonal bottles/jars; octagonal bottles/jars.

Seal head integrated in the system compatible both with front/back configurations (double head) and with single-head configurations.

It allows the application of seals of any shape, including round seal; square seal; rectangular seal; irregular-shaped seal.

It ensures centering and stable adhesion on caps made of plastic, metal or glass.

PRODUCTION SPECIFICATIONS: Output varies depending on container format, label size and application configuration (front-only, back-only, front/back or seal).