Description

TYPE: Heated stainless steel mixer, designed for mixing products with controlled temperature management.

The unit integrates a vessel heating system and a central pneumatic agitation group, ensuring uniform product treatment during the preparation phases.

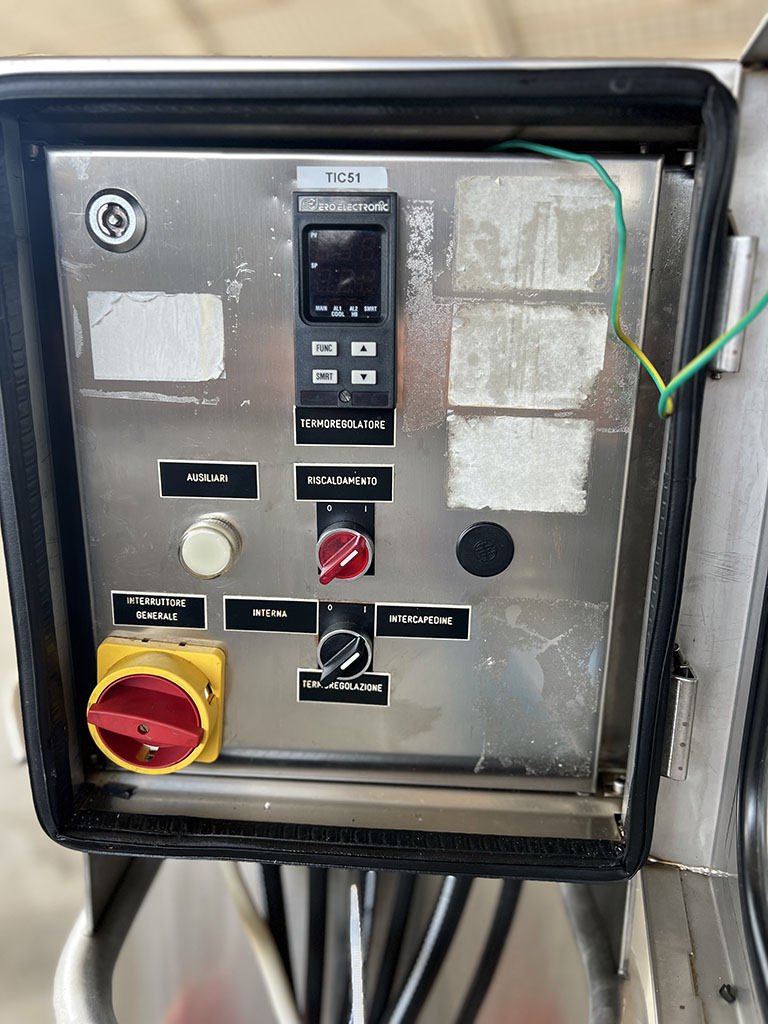

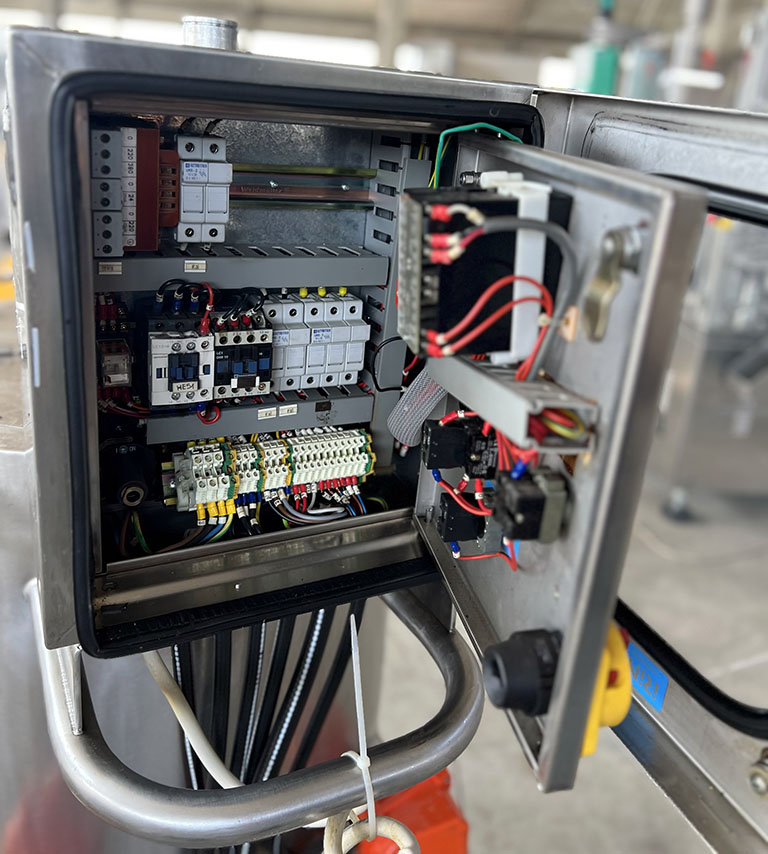

KEY FEATURES: Compact design with stainless steel construction, suitable for both production and laboratory environments. Easily movable thanks to the installed wheels. Integrated heating system designed for processing products requiring controlled temperatures up to high levels, while maintaining mixture stability and uniformity. Central pneumatic shaft agitator, suitable for liquid and semi-dense products. Stainless steel electrical control panel equipped with temperature controller, main switch, and separate controls for agitation and heating. Ideal solution for small batches, production tests, pilot preparations, or integration into existing preparation departments.

TECHNICAL FEATURES:

Inner vessel capacity: approx. 133 liters

Jacket: 40 liters

Maximum operating temperature: 90 °C

Operating pressure:

Inner vessel: atmospheric

Jacket: 1 bar

Stainless steel electrical control panel with temperature regulation

“CE”

PRODUCTION SPECIFICATIONS: Production output and cycle times depend on the processed product, its viscosity, and the set temperature and agitation parameters.