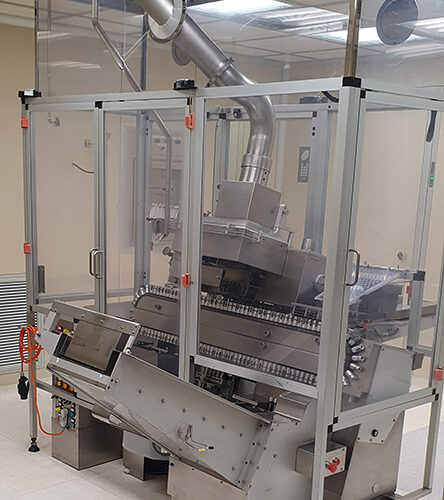

Description

TYPE: Integrated primary + secondary automatic packaging line for powder and granule stick-packs, with volumetric auger dosing, in-line weight control, variable data management and automatic cartoning with leaflet insertion and labeling.

KEY FEATURES: Complete packaging line starting from laminated film and ending with labeled and weighed cartons, with in-line quality controls on all critical steps: variable data printing, visual verification, dosing, sachet weight control, counting, cartoning, leaflet insertion, hot-melt glue closing, carton weighing and label application. The line is controlled by PLC with automatic rejection logic for out-of-specification sachets or non-conforming cartons, ensuring operational reliability and batch traceability.

Overhaul status: in 2020 the line underwent a structured mechanical overhaul on kinematics, transmissions, moving parts and wear components, improving running stability, production continuity and reducing the risk of machine downtime.

TECHNICAL FEATURES:

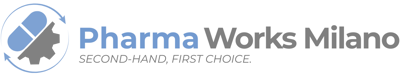

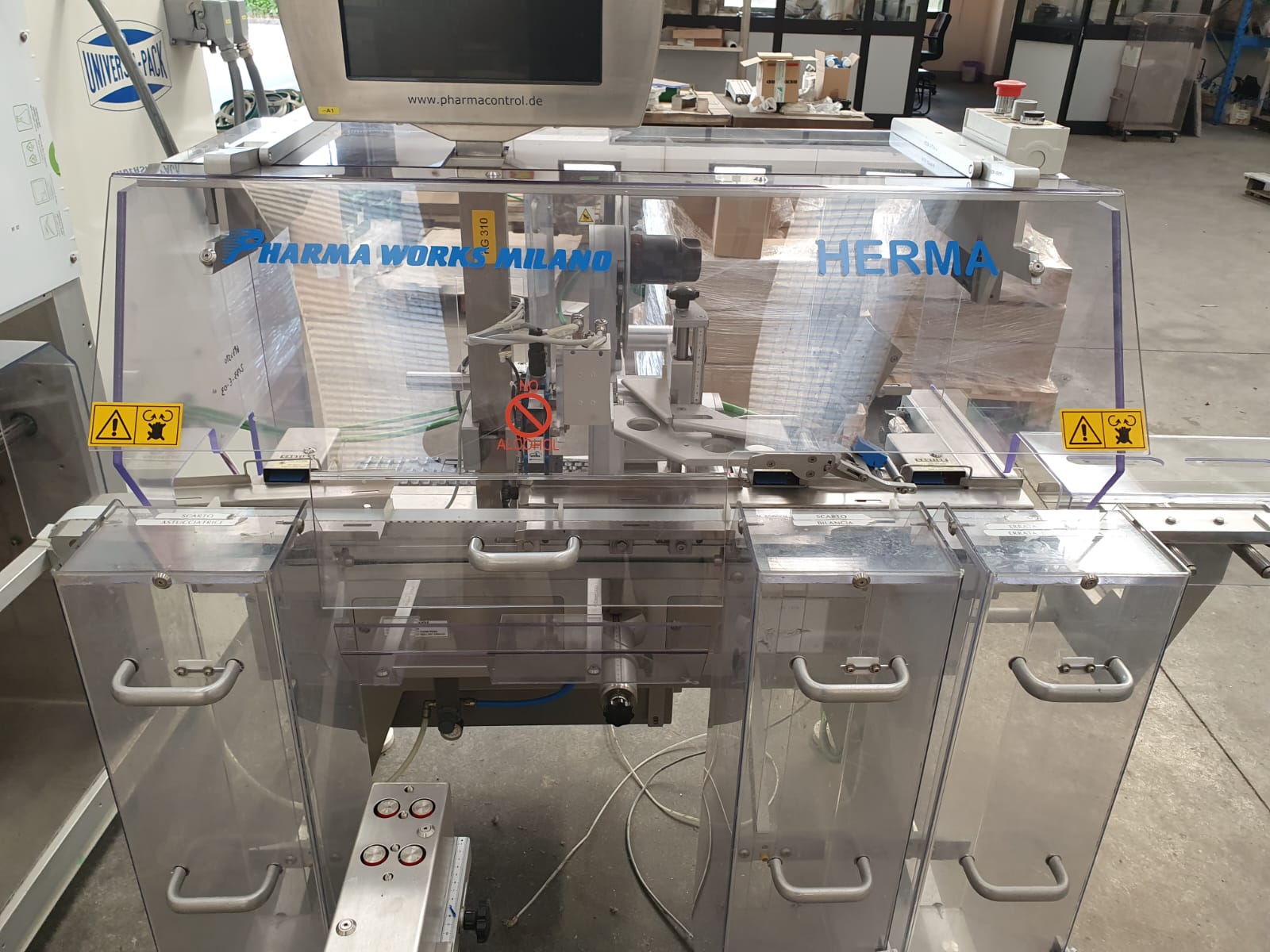

Tubular sachet machine Alfa G20C

Pick & Place R80/V

Horizontal cartoner Delta 120

Leaflet folder Saturno

In-line carton weight control

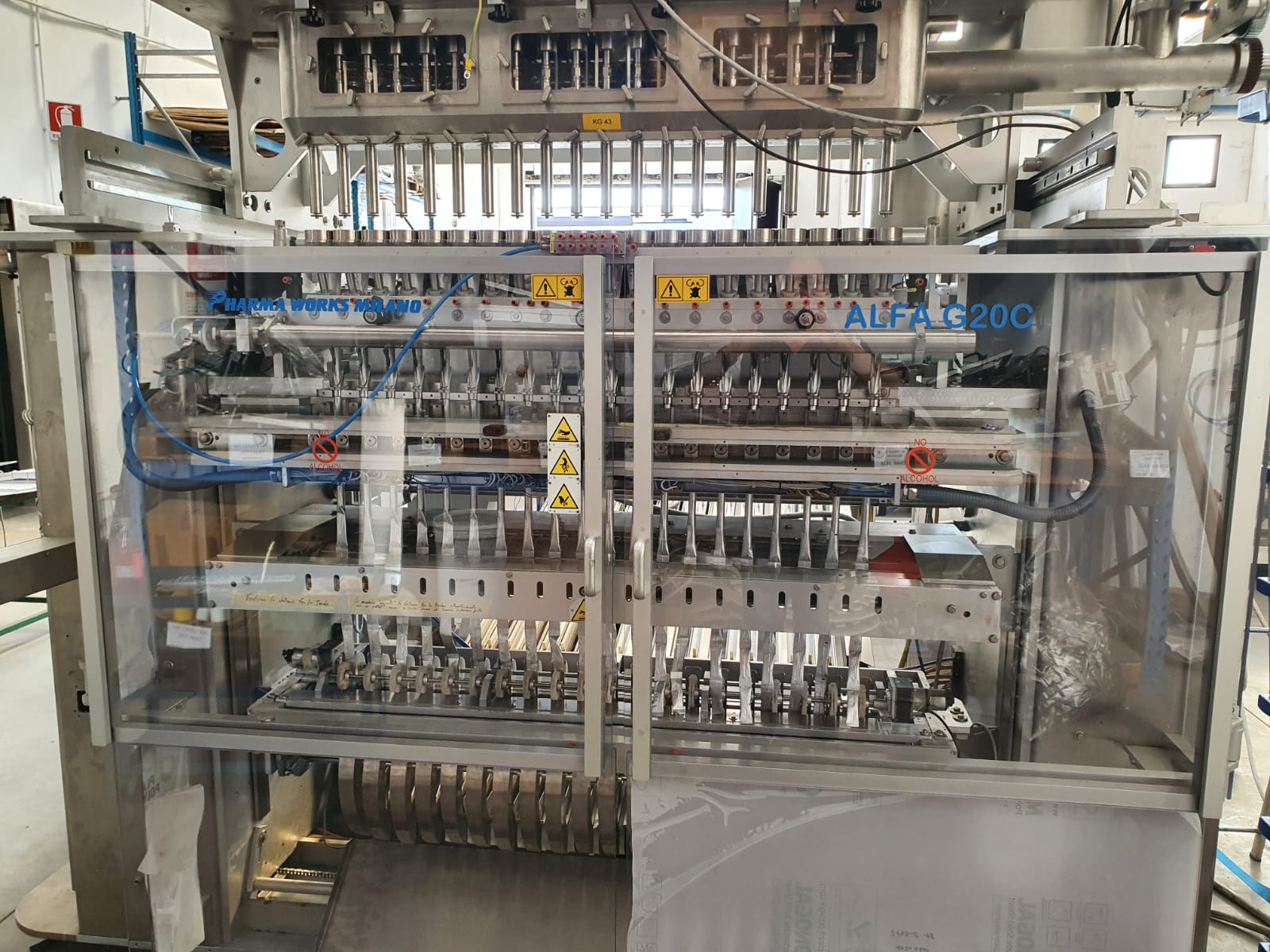

Labeler Herma

Auger doser for powders and granules

Heat-sealable laminated film: paper/Alu/PE or PET/Alu/PE

Sachet width: 26 mm

achet length: 90–110 mm (operating range 70–200 mm)

Power supply 400 V – 50 Hz

Installed power 32 kWA (49 A)

Compressed air 6–7 bar

Air consumption 100 + 50 l/min

Dust extraction

-

2 suction pipes → 240 m³/h at 1400 Pa

-

4 suction pipes → 340 m³/h at 1400 Pa

FORMATS AND PRODUCTS HANDLED

Stick-packs

Format 26 × 120 mm — 5.9 g

Format 26 × 90 mm — 2.95 g

Adjustable sachet length range 70–200 mm

Available cartons

Type A: 120 × 65 × 130 H — 30 sticks + leaflet

Type B: 95 × 55 × 130 H — 20 sticks + leaflet

Type C: 95 × 40 × 130 H — 14 sticks + leaflet

Type D: 95 × 65 × 100 H — 30 sticks + leaflet

Type E: 95 × 65 × 100 H — 30 sticks + leaflet

PRODUCTION SPECIFICATIONS: The line is designed for continuous operation with an adjustable speed up to 60 cycles per minute, allowing potential production of approximately 72,000 sachets per hour, depending on sachet format, powder characteristics and process settings. Dosing is performed volumetrically by auger in a typical range of 3–7 g per sachet.