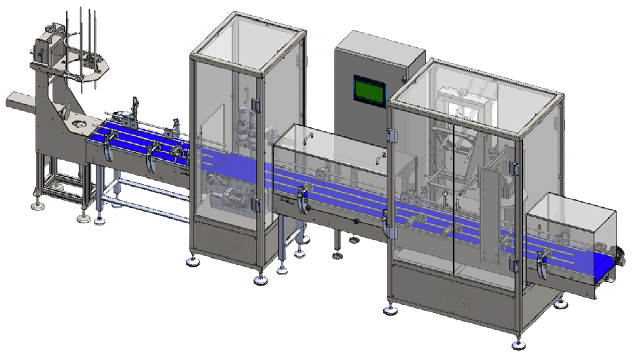

BUCKET LINE

BUCKET LINE

represents the ideal solution for

the dosing and capping automation process in cases where there is a

need to fill buckets. It is suitable for handling liquid, semi-dense or

dense products in glass and plastic jars with wide application in the

food, cosmetic and chemical sectors.

FUNCTIONS

At the beginning of the line, it is possible to foresee the insertion of an

automatic destacker to automate the bucket loading operations.

The dosing station with specific pumps chosen based on the product,

temperature and dosing range, are integrated into an automatic

weighing system with belt and scale.

The capping station can be semi-automatic, with the lid being placed

by the operator, or completely automatic using a system of placing and

applying with a suction cup tipper.

At the end of the line, the lid pressing station closes the pressure

container with an adjustable plate and special locking pliers.

VERSIONS

The system can be supplied with a single or multi-head dosing unit and

include the addition of a loading and capping station.

At the end of the line, it is possible to add as an option a labelling system

with batch printing, curved accumulation belts, a heat-sealing station or

other components suitable for completing the packaging cycle.

WITH BUCKET UNSEALER AND AUTOMATIC CAP LOADING

DOSING VERSIONS (kg)

Up to 30 kg

PRODUCTION SPEED

Up to 350 pcs/h on 3 kg format

TYPES OF VASES

Lenght: up to 300 mm

Height: up to 350 mm

SUPPORTED CAPS

Up to Ø 300 mm

SYSTEM DIMENSIONS

Lenght: 5.000 mm

Height: 1.800 mm

Depth: 1.100 mm