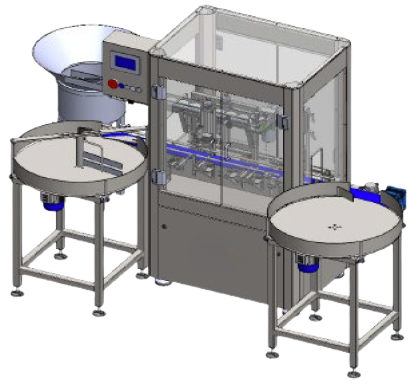

EASY FULL AUTOMATIC

EASY

represents the ideal solution for the

filling and capping automation process in cases where there is a

need to have a streamlined, versatile and small-sized system to start

or improve the production process of one or more products.

It is suitable for handling liquid, semi-dense or dense products in

glass or plastic jars with wide application in the food&beverage,

cosmetic and chemical fields.

FUNCTIONS

The machine is equipped with a control panel with dedicated touch

screen through which it is possible to set the processing recipes,

adjust the operating speed, activate the washing cycle and manage all

the main functions. The system can be created with the predisposition

for interconnection to the IT-company-system.

VERSIONS

Designed to minimize overall dimensions, it is also a modular solution

as it can be created both in the basic version, with the manual loading

of the caps resting on the transport belt by the operator, up to the

full automatic version with the insertion of the rotary tables the

vibrating orientator for serving the caps to the line.

The small size of the EASY line optimizes production spaces and for

this reason it represents the ideal solution to automate the packaging

process, producing up to 2.400 containers per hour.

WITH ROTARY TABLES AND VIBRATING ORIENTER FOR CAPS LOADING

DOSING VERSIONS (ml)

Volumetric Pump from 0 to 38

Volumetric Pump from 2 to 100

Volumetric Pump from 5 to 380

Volumetric Pump from 20 to 680

Volumetric Pump from 50 to 1300

Volumetric Pump from 100 to 2100

PRODUCTION SPEED

Up to 2.400 pcs/h based on the format

TYPES OF VASES

Lenght: fino a 80 mm

Height: fino a 210 mm

SUPPORTED CAPS

Twist-off and screw caps

Up to Ø 90 mm

SYSTEM DIMENSIONS

Lenght: 2.800 mm

Height: 1.785 mm

Width: 1.700 mm