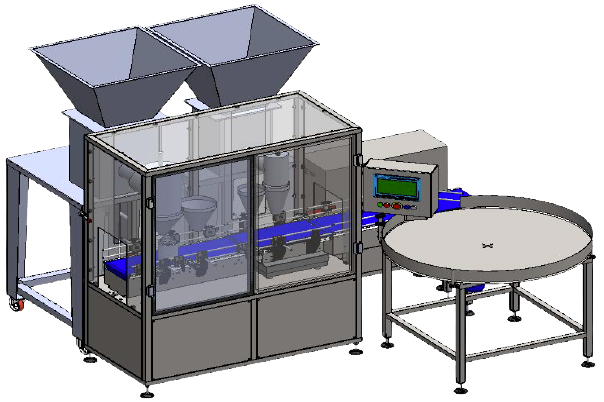

POWDER LINE

POWDER LINE

allow you to independently

manage the dosing, capping and labelling process for packaging

various types of powders, even those that are not very free-flowing

and tend to aggregate.

The screw or vibrating channel dosing units are highly reliable and

precise and are chosen based on the project and the required speeds.

We can offer majority and minority dosing groups or multi-head weight

systems specifically designed to be able to integrate suitable suction

units.

The capping station performs the function of positioning any type of

lid on the bottle using vibration systems with pick & place or lid

placement and application systems and close them adequately with

our capping units.

To complete the packaging cycle, labelling, marking and ad hoc

solutions for the end of the line are integrated upon request.

Our engineering team is able to adapt the various components of the

system to the specific needs of the project.

VERSIONS

The system can be supplied with multi-head dosing groups up to 6

filling units integrating capping solutions that allow to reach production

speeds up to 1.600 pcs/h.

It is also possible to foresee the insertion at the beginning of the line of

a bucket denester to automate the container loading process.

AUTOMATIC POWDER DOSING LINE

DOSING VERSIONS

Up to 30 kg

PRODUCTION SPEED

Up to 1.600 pcs/h on 400 gr format

TYPES OF VASES

Lenght: up to 300 mm

Height: up to 350 mm

SUPPORTED CAPS

Up to Ø 300 mm

STANDARD SYSTEM DIMENSIONS

Lenght: 5.000 mm

Height: 1.800 mm

Width: 1.500 mm

With tailor-made customizations