START LINE

START LINE

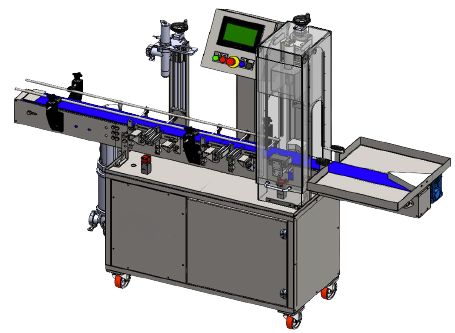

is an automatic line suitable for packaging liquid and

dense products that finds wide application in the food and cosmetic

sectors for its ability to be adaptable to the different formats of

containers and caps and for its ease of management. The separation of

the dosing station and the capping station allows to create an operator

space for the manual placement of the cap, thus proving to be very

appreciated by all companies that need to produce a multiplicity of

products with different containers and caps.

The format change occurs quickly through simple manual

adjustments that allow to adapt the stations to the new container.

It allows to reach a production speed of up to 800 units per hour on

an average format of 250 ml.

FUNCTIONS

The empty container is transported to the dosing station which can be

equipped with up to two dispensing nozzles with the possibility of also

providing immersion dosing for foaming and high-temperature

products.

The operator station, in front of the touch screen control panel, is

equipped with a cap tray for collecting and positioning the caps on the

neck of the container.

The capping station, with special polycarbonate protections, concludes

the packaging process by closing the cap using special spindles or

custom solutions capable of managing a variety of commercially

available caps.

It is possible to provide for the insertion of a rotating table at the

beginning of the line for loading the containers.

DOSING AND CAPPING ON CONVEYOR BELT

DOSING VERSIONS (ml)

• Volumetric Pump 0 A 38

• Volumetric Pump DA 5 a 100

• Volumetric Pump DA 5 A 250

• Volumetric Pump DA 20 A 680

• Volumetric Pump DA 50 A 1.300

PRODUCTION SPEED

Up to 800 pcs/h depending on the format

and on the operator

CONTAINER DIMENSIONS

Lenght: up to 200 mm

Height: up to 350 mm

TYPE OF CAPS

• Twist-off caps

• Screw caps

• ROOP caps

• Flip top

• Trigger o Dispenser

• Other types of caps to evaluate

SYSTEM DIMENSIONS

Lenght: 2.000 mm

Height: 1.700 mm

Width: 560 mm